Everything You Need To Know About Clean Room Maintenance

A clean room is a facility ordinarily utilized as a part of specialized industrial production or scientific research, usually in the manufacture of pharmaceutical items and microprocessors. They are designed to have extremely low levels of particulates, such as dust, airborne organisms, or vaporized particles.

Extensively used in semiconductor manufacturing, biotechnology, and life sciences, these rooms must maintain less than 12 particles per cubic meter of 0.3 μm and smaller, and no particles above that size. Due to this fact, maintaining and cleaning clean rooms is a highly specialized task, and requires a high level of expertise.

Discussed below are some important processes and procedures that are integral for the maintenance of clean rooms of any kind.

1. Cleaning and disinfection

Cleaning and disinfection are separate processes, meant to achieve separate goals. Doing one of them does not necessarily mean that the other is done as well. However, both of these processes are required for proper maintenance of clean rooms.

Cleaning refers to the removal of dust and dirt. The cleaning process for clean rooms can be summarized in three words: vacuum, wipe, vacuum. Vacuuming or tack rolling is done to remove loose particles from the surfaces. Wiping provides a way to loosen and remove more tightly bound particles. The final vacuuming is done to remove loosened particles and cleaner residues.

Disinfection, however, is used to take care of biological microorganisms that might be present in the clean room. They are bactericidal, sporicidal, or both in nature. Ideally, disinfection should be done before cleaning, since then the disinfectant residues can be cleaned along with other impurities in the clean room.

2. Selecting appropriate cleaning agents

It is vital to know that regular cleaning agents are not useful when cleaning clean rooms. They require specialised, heavy duty cleaning agents. Any detergents that are selected for clean rooms must be neutral, non-ionic, non-foaming, and compatible with disinfectants.

Similarly, while selecting disinfectants, care should be taken to make sure that they are wide spectrum, rapid action, and non-reactive with detergents, and should work at the temperature that the clean room operates in. It should also not damage the material that it is applied to, and comply with health and safety standards.

Also, cleaning materials used to apply disinfectants and detergents must be appropriate. They should be clean room certified and non-particle shedding (non-woven and lint-free).

3. Inspecting the clean room

The main test to check how clean and well-maintained a clean room is through environmental monitoring of clean rooms. This is assessed by sampling various surfaces with contact plates and swabs, and testing the samples. These give information about the various levels of microbiological and non-organic contaminants present in the clean room.

If the levels are above what is considered legal or company standards, then the maintenance process is not up to par. Conversely, if all the samples fall below the accepted standards, then the clean room is indeed clean.

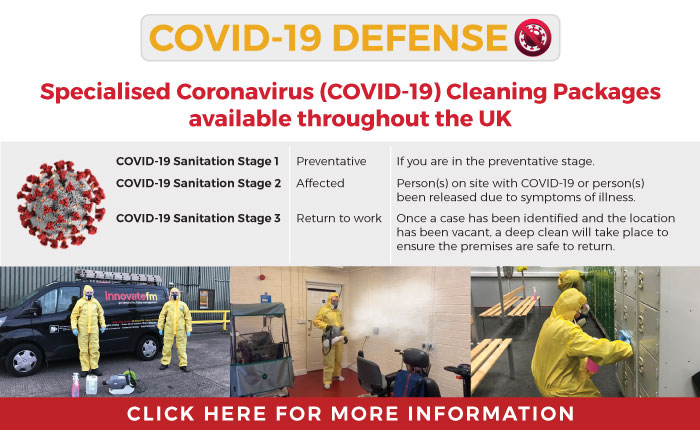

Specialised clean room maintenance for all kinds of facilities

Our staff at innovatefm are highly trained and competent, able to thoroughly sterilise clean rooms for all kinds of facilities, ranging from pharmaceutical manufacturing and biological research facilities, to food and beverage manufacturing.

We also provide a comprehensive range of other kinds of commercial cleaning solutions, such as window cleaning, restroom maintenance, and carpet cleaning.

Give us a call on (0161) 724 8999 (option 1) or email us at enquiries@innovatefm.co.uk for more information.